The check sheet is the effective, efficient, and simple way to depict data and information. A check sheet is a structure table, metrics table, or form for gathering data to analyze it. When the information or data are gathered in both quantitative and qualitative data, then the check sheet remains check sheet, but it can also be referred as a tally sheet. In this article we will review what types of check sheet are used in manufacturing.

The purpose of the check sheet is to write down the crucial events or checkpoints in a metrics/tabular format and keep update or mark the current status on all happenings which assist in understanding the performance and progress. The check sheet makes you aware of the defect patterns and the causes of it.

When and Where to Use the Check Sheets

The use of check sheets is appropriate when information can be collected and observed again and again by either at the same location or the person. It is truly the only efficient tool to gather data and information on frequency and detecting the problems, patterns of events, defects and their location and causes.

Types of Check Sheet Used In Manufacturing

Let’s review the different types of check sheet used in manufacturing, but before that we need to know more about manufacturing check sheets. They are handy for both quantitative and qualitative data collection and analysis in manufacturing.

The check sheets assist in gathering and organizing the data systematically, and they are useful in all the process of manufacturing (production, packaging, safety, and inventory)

Manufacturing Check Sheets

There are many types of check sheets used in manufacturing, such as tabular tally sheets or check sheets, concentration or location diagram, and distribution or graphical check sheets. We will talk about them one by one and why they are helpful in manufacturing.

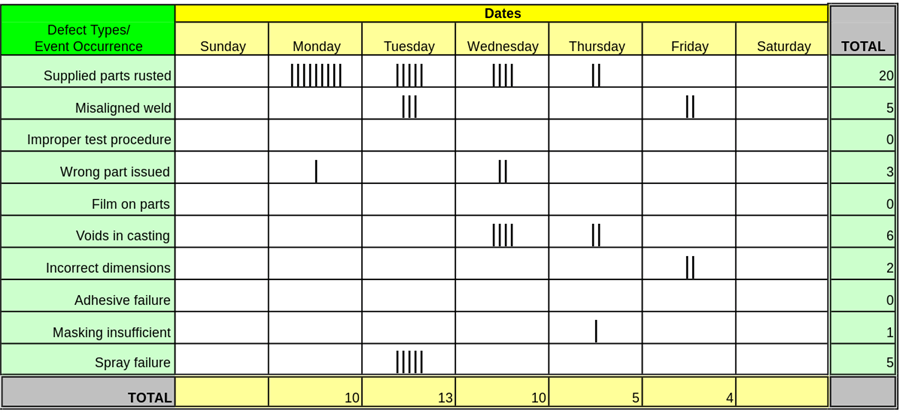

Tabular Tally Sheet or Check Sheet

One of the common types of check sheet used in manufacturing is a tabular tally sheet or check sheet to gather data on quality issues and to check the frequency of process. For instance, the tally sheet is helpful in comprehending the reasons why raw materials supply is delayed for the production process, causes of delays and much more. It is helpful in defining the occurrence frequency, such as quantity of raw material in the warehouse on different occasions to understand the requirement for raw material.

Concentration or Location Diagram

For instance, when anyone rents a vehicle, he or she mostly receive the document file of the vehicle and the file also contains the car sketch which let you mark the damages, scratches, or dents on the vehicle with a relative mark on the design. This is how the concentration or location diagram works. Similarly, you can separate the defected items in the manufacturing stage.

Another helpful thing about the location diagram, this check sheet does not just determine the number of defects, but the defected areas can sometimes disclose the product area where production team is witnessing most of the flaws. After knowing this, the team can look at the process and rectify things to prevent them in the future.

Distribution or Graphical Check Sheets

With the assistance of graphical form, the employee gathering the information and data can visualize the data distribution. For instance, the number of products in the line for packaging in the packaging department at a 20 minutes interval could be tallied to decide the staffing needs and potential of the packaging machinery.

Benefits of Using Check Sheets in Manufacturing

We are reinforcing here that check sheets are effective and easy way to show the information and data. It is an indeed a first step that depicts current status of manufacturing and shows the defected products and cause of those defected products. It uniformly gathers the data. It is also advantageous to assist different data through facts and numbers for decision making in manufacturing.

Conclusion

We reviewed types of sheet used in manufacturing and here are many processes within the manufacturing stages where check sheets are helpful tools to make the manufacturing stage effective and efficient.