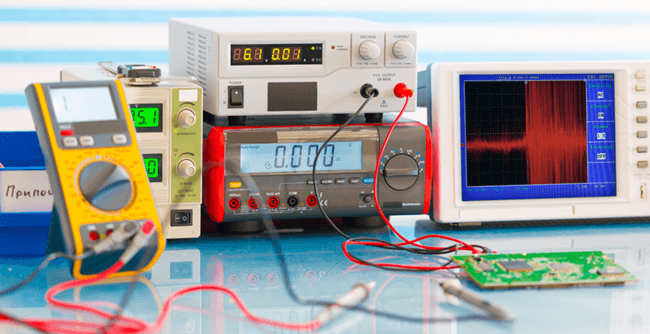

In this modern era of technology, it is important to use accurate measuring devices to measure the physical quantities around us. Accurate measurements are facilitating several industries. From weather to medical, from the automotive industry to agriculture, accurate measurements are essential for decision making. These measurement devices are required to provide correct information. These devices should have to be verified and accurate as much as possible. The calibration of measuring instruments is ensuring the accuracy of the gauges.

What is calibration of measuring instruments

Calibration of measuring instruments is an association between standard measurement and analysis using your equipment. It is the process of checking the reading of the device to see how the measurement compares to the true value. The accuracy of the standard is required to be ten times the accuracy of the measuring instrument. Calibration of measuring device have two most significant objectives. It is used for determining the accuracy of the tools and it checks the traceability of the measuring instrument. Calibration is also important for repairing a device if it is not performing well.

Inaccurate instruments can cause electrical or mechanical shocks, or it can make the manufacturing environment hazardous. Type of the instrument or the environment in which it is being used can degrade the instrument. In this regard calibration is the only way to improve the accuracy of the measuring devices. Calibration through making the measuring devices accurate would be able to improve product quality as well. In order to explore more about calibration and to know the importance of calibration, you have to go through the article completely. The later part of the discussion will cover some reasons why calibration is important.

Traceability

The accuracy of an instrument is dependent on the traceability of the instrument. Calibration ensures that the reading from the instrument is consistent with other instruments. In other words, the results of the measuring device are useful if they relate to similar measurements. Traceability allows manufacturers to control the manufacturing process by controlling activities from one day to another and from one place to another. Traceability also allows manufacturers to satisfy client specifications. For example, New Zealand follows SI system of measurement. It includes a definition of meter kilogram and second. New Zealand can relate their measurements in any other country using SI system of measurement.

Uncertainty

Calibration determines the accuracy of the instrument readings. Accurate measurement enhances the quality of decision whereas poor quality measurements result in poor quality decisions. Uncertainty is the estimated numerical value which helps in minimizing risk and possible poor consequences. Calibration defines a particular numerical value for uncertainty and enhances the quality of decisions. When making decisions accurate uncertainty in measurement is as important as the measurement itself.

Reliability

Calibration of measuring instruments ensures that the instrument has the ability to provide reliable information. Calibration ensures that there are minimum corrections and uncertainties in the measurement of a particular device. Reliability is the measurement of a device for the behavior that can indicate that the device is faulty. The device is reliable if there are no chances of error. Calibration certificate ensures that the tool is reliable and it can satisfy the intended purpose.

Conclusion

The above discussion highlighted that calibration of the instrument is essential for gaining accurate information about the measurement of physical quantities. Calibration also facilitates the process of decision making in all fields of life. In order to enhance the quality of the actions in all walks of life, it is important to calibrate your device according to a recommendation from the manufacturers. Calibration is also necessary after any mechanical or electrical shock. You can calibrate your devices monthly annually or quarterly. Moreover, the hidden cost and risk associated with measuring equipment not being-calibrated are much more than the cost of calibration. Therefore it is highly recommended to calibrate your devices from a reputable company and to ensure that the errors associated with measurement are in acceptable.