The concept of “Lean manufacturing or lean production”, or basically “lean“, means an organized process for waste minimization (“Muda”) without losing productivity in a manufacturing system. Lean tools and processes can be very effective in our way to guzzling waste from the operations of our supply chain.

What Is Lean Milk Run

The term of milk run is used for the method of delivery, and derives from the delivering method of the daily required milk. It is defined as traveling the minimum distance but with the maximum demand in the truck carrying that demand. Milk run is one of the lean tools with the objective to upturn the regularity of supply by being economical and cost-effective. Indeed, it is an effective approach to accomplish the three concepts of central lean logistics including lot size decrease, increased delivery frequency, and leveled flow. In lean milk run the focus is on creating a level where each involvedtruck cover deliveries part in a closed traffic circle rather than delivering merchandises to costumers on single trips from the supplier.

By following this approach we can enjoy lots of benefits to cut wastes as it results in increased frequency of delivery does not influence on the freight cost, increased inventory turnover is accomplished and reduced amount of stock is possible. Lean milk run is characteristically a specific of lean manufacturing and it is only probable when suppliers are to be found in nearby locality of the parent company. Therefore, those business entities that follow lean concepts assemble the parts or materials every day and in some cases even on an hourly basis. This suggests that the parts or materials are served right on the assembly lines of parent enterprise. As a consequence, there is no need to keep any inventory of such parts or materials for the parent company in their stocks. The deliveries frequency is high and therefore the inventory is in a smaller amount or insignificant at the parent companies.

Previously, suppliers were not placed in the locality of its parent company and therefore the lead time for procurement was higher due to the huge distance between supplier and parent company. This verity forced the parent companies to maintain more inventories in their stores because of increased lead times. This means that the parent companies are turning over the money of transporting increased inventories from their side to their suppliers. Implying the fact, that at the parent company the inventory level decreased without any doubt. On the other hand, the responsibility to maintain adequate inventories then lies direct on the suppliers at their end. So in light of that we can say that milk runs decrease inventory levels at the parent company, however, not essentially at the end of suppliers.

The concept of lean milk run logistics has been designed to develop loading charges at feasible levels and decrease trucks numbers and distances of travel. Accordingly, it is an outstanding transport system in which exhaust gases from trucks can be managed effectively. Hence, the encouragement of lean milk run can be assessed greatly from the perspective of ecological policy. Furthermore, a metropolitan logistics policy can be commenced to enhance transportation dependability as the lean milk run needs precise management derived from the operational plan. A road infrastructure that can create doable planned functions and a road quality that does not become the source of damage to the transported merchandise are vital for developing countries. As far as developed countries are concerned, policies for instance road-use control schemes could be launched with high load aspects in order to prioritize vehicles. Additionally, consolidation using consistent returnable packages and containers are applied to boost transport competence in milk run logistics.

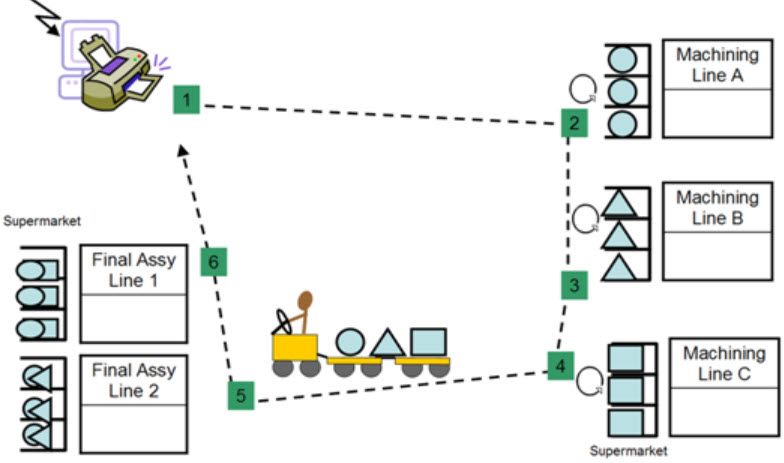

Lean Milk Run in Production Structure

Furthermore, in the production structure if lean milk run is utilized for the supply purposes the materials in the production line; the transportation cost is reduced on the whole and most advantageous utilization of the resources is possible. Milk run logistics is executed by means of working closely and direct links between the automobile manufacturer, logistics service provider, parts supplier, and its control on local transport turns out to be more momentous if the range of the milk run logistics becomes superior.

Conclusion

In a nutshell, milk run is an entirely private endeavor with financial drive; however it has constructive external consequences for the general public too.