How to Implement the Kaizen Method Within Your Workplace

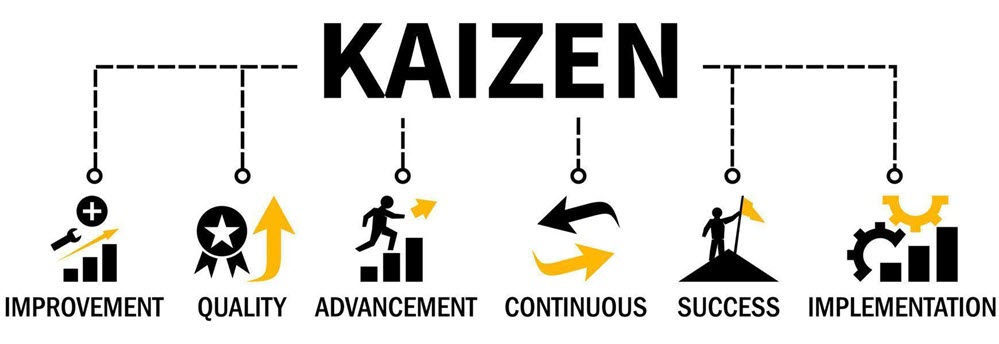

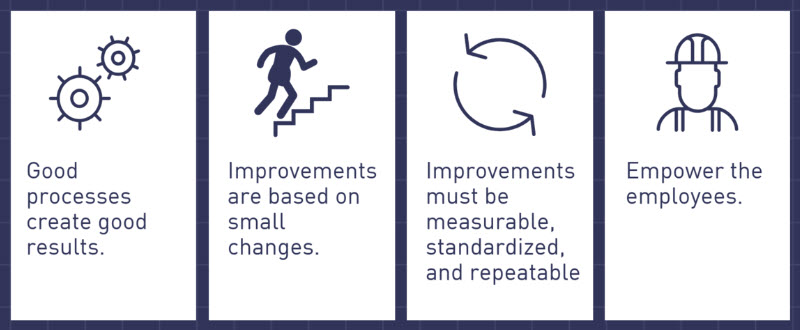

Kaizen, a Japanese term meaning "change for better," is a philosophy and methodology that focuses on continuous improvement. Widely applied in manufacturing, healthcare, and various industries, the Kaizen method aims to enhance productivity, efficiency, and overall workplace satisfaction. In this article, we will explore the steps and strategies for effectively implementing the Kaizen method [...]