What is an ISO 9001 gap analysis?

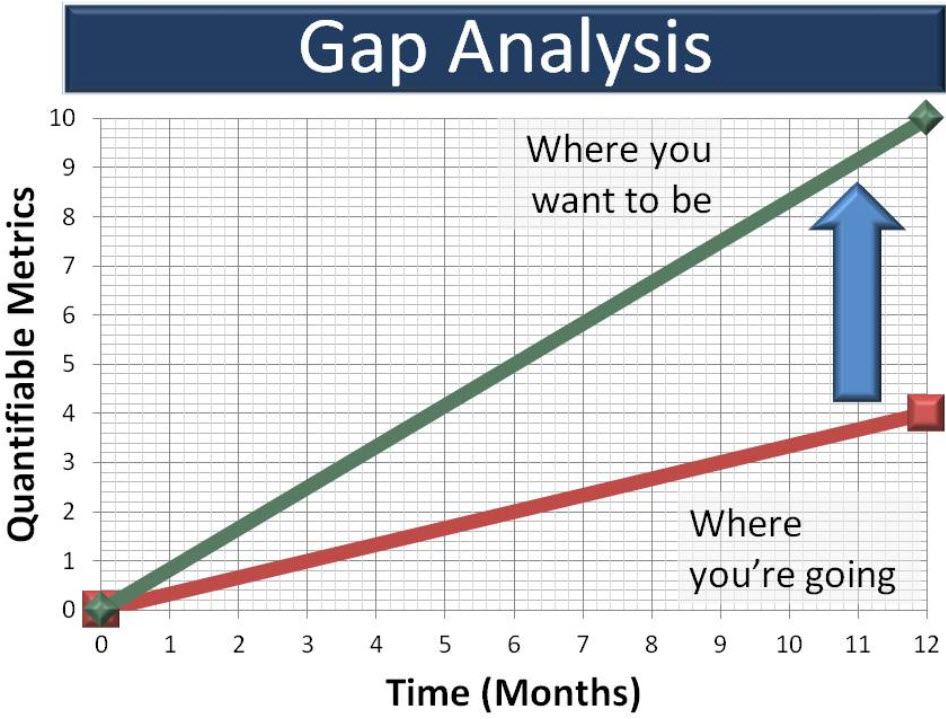

One of the first steps in your Quality Management System (QMS) transition or implementation project is to compare your current QMS to the requirements of the ISO 9001 standard. This is most commonly called a gap analysis.

There are a few recommended steps to be completed before conducting the gap analysis.

- Identify one or more people to conduct the gap analysis. It is helpful if they have some quality system or audit experience. Also it could be an advantage to hire an external consultant with experience in this area.

- You may also want to consider having assistance from an external consultant as for example EQMS Ltd. One important factor when selecting an external consultant, is to ensure he/she is capable, for example by checking they are on the International Register of Certified Auditors (IRCA)

- Create or purchase a gap analysis checklist.

ISO 9001 Gap Analysis Checklist

The most important tool for the gap analysis is the gap analysis checklist. This is a list of the requirements in the standard, written in a question format.

The auditor (person conducting the gap analysis) will use this list to compare the QMS that is in place with the requirement of the ISO 9001 standard. Where there is a shortfall, it is called a gap.

The checklist provides the auditor with recommendations of what documents to look for, examples of what will meet the requirements and other guidance on auditing to the standard. The gap analysis checklist also gives the auditor a specific place to document what they saw that did or did not meet the standard audited against.

Preparing for the Gap Analysis Audit

As part of the preparation for the gap analysis audit, the auditor will create the checklist. The checklist will vary based on what standard the auditor is auditing against. If using ISO 9001 as an example, the checklist will be created based on the content and stated requirements in the standard.

An important factor of the preparation is also to get an understanding of the company being audited, as your gap analysis checklist needs to cover their area of business. For example if auditing a distributor or a manufacturing plant, there would be different areas to access.

Auditing with the Gap Analysis Checklist

The utilization of this checklist, when populated with objective evidence of compliance or not compliance, will satisfactorily demonstrate you have audited against ISO 9001 compliance.

From a process audit approach you may wish to rearrange pages from the gap analysis checklist to group them based on your own QMS process to demonstrate a process approach. There is only one section there is an audit of “management”. Questions throughout the ISO standard are grouped under this process name. The process audit approach doesn’t want to see questions tied to just a single clause of the standard. It wants to see that you’ve grouped questions from different clauses of the ISO 9001 standard against the QMS processes you have defined. When using a gap analysis checklist you can determine where these requirements apply to your specific processes and process approach.