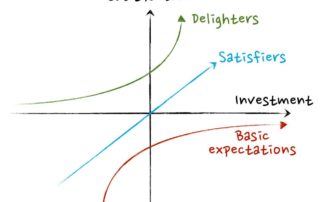

Kano Questionnaire Examples for Customer Satisfaction

Professor Noriaki Kano developed the Kano model in the 1980s; it is a concept of product development as well as customer satisfaction by classifying customer preferences into five groups. It provides strategies to assist us in comprehending customers’ views on the features of a particular product by simply evaluating [...]

Setting up an Efficient Equipment Calibration Program under ISO 9001

An efficient equipment calibration program guarantees equipment works reliably and as planned, and that process control focuses are measured precisely. An efficient equipment calibration program guarantees that measurements are controlled. A satisfactory equipment calibration program can spare time and money by lessening unscheduled downtime. Consistent maintenance can diminish unforeseen [...]

What Customer Experience Methodology Works Best

Customer experience methodology refers to a consumer's experience with an organization or brand, at all touch-points. A touch-point is any way by which a customer can interface with a brand, for example, when buying or using an item or through seeing advertisements highlighting it. Customer experience design centre around [...]

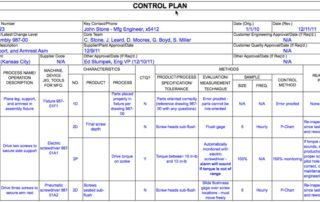

How to Use a Process Control Plan in Manufacturing

The process Control Plan is a report that depicts the activities (measurements, assessments, quality checks or observing process parameters) required at each section of a process to guarantee the process yields will adjust to pre-decided requirements. In easy words, the process control plan furnishes the inspector or operators with [...]

ISO 9001 Document Control Requirements

Documents help to pass across information, enable knowledge sharing and provide proof of conformity. They could be presented in several forms, for instance as images, electronics or paper. ISO 9001 document control requires a company to establish, document, execute and uphold a quality management system and continuously improve its [...]

How to Use Pestle Analysis in Your Organisation

Pestle analysis is a tool expressing the macro environment of businesses. Pestle analysis is a simple and extensively used tool that helps you evaluate the political, socio-cultural, economic, and technological alterations in your business environment. This assists you in comprehending the “big picture” forces of change that you’re open [...]