Root Cause Analysis (RCA) refers to the search for the true causes of a problem. In many scenarios, organisations face failures in some sections or fail to achieve certain goals. They therefore find solutions by tackling the symptoms of the problem instead of its root cause. The trick is to use the appropriate root cause analysis tools and techniques to detect the root cause of the problem at hand. It is not uncommon to find more than one root cause to the problem, as such, you should be sceptical if a problem has just one root cause.

RCA can be used to solve different problems from the simplest to the most complex. Knowing the right root cause analysis tools and techniques is important in that it prevent waste of time and resources, pointing you in the right direction of the root cause of problem. There are different root cause analysis tools and techniques to find out the root causes of any problem including the GOFAAT method, Whack-A-Mole method, TQM, FMEA, etc. We will take a careful look at the common root cause analysis tools and techniques by discussing them in groups.

The Three Groups of Root Cause Analysis Tools and Techniques

Group A Problem Solving Techniques

Guessing One Factor at a Time (GOFAAT)

This technique requires no formal training to employ and can be used to resolve a problem. GOFAAT is not the most precise and effective tool to solve a problem; in fact, it is the last tool to rely on. It is a trial and error means of identifying the root cause of problems. The solver guesses around to find where the problem lies. For instance, a restaurant manager gets complaints from customers about late filling of their orders. After each complaint, he then runs around each complaints and scolds employee Doe today, then employee Lola and Kate the following day and the cook the day after. Solving problem with GOFAAT is common, yet an ineffective technique to find the root cause of any problem.

Professional Techniques

- Total Quality Management (TQM)

- Failure Mode and Effect Analysis (FMEA)

- Plan-Do-Check-Act (PCDA) continuous improvement

These root cause analysis tools and techniques are more professional approach for solving problems. They can only be employed by individuals or teams after some amount of specialty training. TQM, FMEA and PCDA can be used to identify root causes of low complexity problems with the use of team agreement, debate and team voting.

Data verification and advanced statistics are not usually used when solving problems with these problem solving techniques. These techniques are only effective in solving simpler problems and not complex. They are not the best and may not always get the root cause right, however their efforts will go a long way, if employed correctly.

Group B Problem Solving Techniques

- Time and Motion Studies

- Lean Manufacturing and Lean Office

- Process Mapping

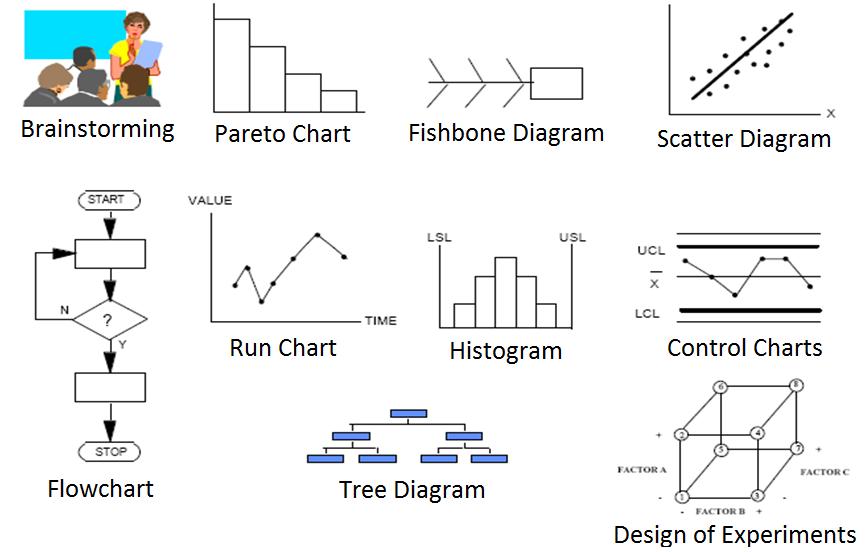

- Seven Basic Tools of Quality

- Lean Kaizen Events

- Six Sigma or Lean & TRIZ

The success of these techniques for identifying root causes of problems greatly depends on availability of very accurate data and information. These techniques will easily crack simple customer problems like the restaurant complaint about late filling of order mentioned earlier. Anyone with a Lean Six Sigma Green Belt or black belt can easily solve these types of problems using the right tools. Like the professional techniques in group A, specialized training is also required to effectively execute these root cause analysis tools and techniques. Techniques in these groups are applied to solve complex problems that Group A techniques cannot handle.

Group C Problem Solving Techniques

- Statistical Hypothesis Testing

- 3D and Multi-stratification-level graphing

- Multiple Variable Regression

- Simple Regression Analysis

- Artificial Intelligence

- Neural Networks and DOEs

From a glance, these are obviously complex techniques that require more accurate data about the problem to be analysed. The analysis will be carried out with specific software to make the problem solving technique successful. These tools could be used to evaluate production default problems within an organisation. To use these root cause analysis techniques and tools, the solver must possess certain skills that would only be possessed by Lean Six Sigma Black and Master Black Belts and other highly qualified professionals. These techniques are the last resort when effort from other techniques fails to identify the true root cause and solve the problem.