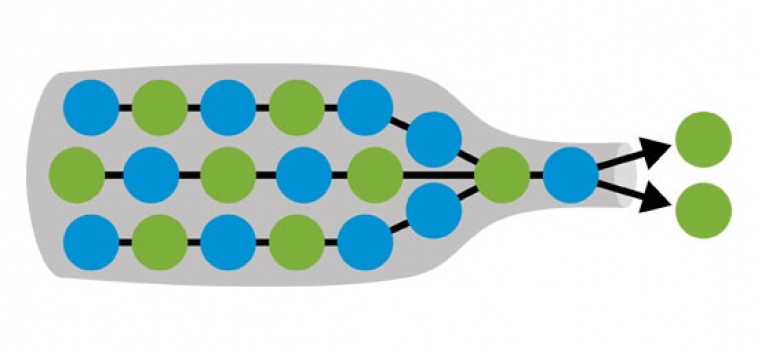

Well, to say it simply, a bottleneck in operation management is a point in production where a process meets or even exceeds the ability to manufacture. To make things easier, it is when a department or a factory can’t produce the required units fast enough to maintain the remaining production schedule or to let the other daily processes moving at the same pace. It is similar to how an ordinary glass bottle tapers at one end. This happens the same way with the production process as the units cog up at the bottleneck operation which slows down the entire production process.

Anything that interrupts the rapid flow of your work is what we refer to as a bottleneck in operation management. Every other company faces a bottleneck at some point. In the below guide to remove bottlenecks, I will tell you how to identify and remove a bottleneck in operation management and how to keep them from happening again.

Spot the Bottleneck in Operation Management

It isn’t that difficult to spot a bottleneck in operation management. Why is that so? Because all the work input usually piles up ahead of the bottleneck process. Thus, workers in the next operations stand idle, or they work under capacity. Therefore it is mandatory to describe the bottleneck process in quantitative terms if it is possible. For instance, suppose the total manufacturing capacity at your end is 1000 units per hour, but because of your bottleneck state, you only manage to manufacture 500 per hour. Here, you need to identify all the measures that contribute to the bottleneck. You might need a few extra shelves to manage the inflow work. You should focus on the situation of the constraint.

Get the Most out of Bottleneck Limit

You need to find out ways to get the maximum out of the bottle capacity under the present conditions without adding any additional expense. If you think that the reason of your bottleneck is the inefficiency of the equipment, then you might think of rescheduling the production. In this way, you can get the most out of your bottleneck with minimum expense. If you find out that a few workers are working above the bottleneck speed, then it might be the time to train all those workers who don’t. You can also look for the bottlenecked process. That is, if the input work is inconvenient for a machine operator to get to the machine, then neither the worker nor the machine can work at full capacity.

Regulate Non-Bottlenecks

After you have maxed out the bottleneck capacity, then you need to adjust the remaining points in the whole process which will match the entire bottleneck flow. One thing that you can do is to reduce the speed at which all incoming work approaches at the bottleneck function. It will remove the extra material handling and might free the staff at the input level. To minimize the wait time at the later stages by matching the output of bottleneck. This stage places its entire focus on the flow of work that is through the whole process, which will lead to a maximized efficiency and minimal wasted effort.

Spend on Your Bottleneck

If you followed the above steps and things still aren’t working out for you, that is, you are again falling short and not meeting the demands of your company, then it is high time to elevate the bottleneck. What you can do is to add extra machinery or hire more workers. It may lessen the bottleneck effect, but it will also bring significant expense to your company since substantial capital purchases take away funds from your entire cash flow, adding excessive financial expenditures. The more the workers, the more the production cost. Hence, it results in reduced profitability. You should only consider elevating your bottleneck when you have tried every other possible way to fix the bottleneck.

Analyze the Process

The process to remove bottleneck is a long and ongoing improvement procedure which is devoted to optimizing the workflow. Be careful when you are changing the overall workflow of your production process because every change needs analysis. It means that you are going back to the first step and understanding the true effect on the bottleneck performance. By a thorough overview, you will be able to remove any fixture which supported the root cause of bottleneck condition.