The gage repeatability and reproducibility (Gage R&R) analysis is an essential part of a Quality Management System (QMS) in any organization. This study states that whether the measurement system is adequate for its destined use or not. It also tells which part of the measurement system is reinforcing the most to the deviations of measurement and assist the operator to enhance the system.

In some circumstances, the gage R&R analysis might be the only study to find out dormant flaws and faults in the measurement system. This analysis is designed so as to measure the latent variables and repeatability and reproducibility are considered to be the primary variables. This study also helps to analyze the plenitude of a variation and try to mitigate the problems found.

Personnel Required

For carrying out gage R&R analysis usually three people are required. They can be either from manufacturing department, quality control or laboratory machinist etc. the laboratory machinist is always a good option as they have a vast knowledge about measurements and access to gage R&R apparatus as well.

Settle Gage Problems

If there are any problems associated with the gage it needs to be resolved first. The problems such as non professional technicians, broken pins, damaged cables or software issues etc. can largely affect the results of the analysis.

Gage Calibration

After resolving any issues associated with the gage, it is necessary to calibrate the gage against a standard to get the best possible results.

Scrutinize the Gage Resolution

This step in the process is really important. The resolution of gage adequate to characterize different values that comes in a tolerance range. According to a general rule set, a gage should be capable enough to characterize a minimum of 10 values within the tolerance range.

Sample Collection

It is the most important step in gage R&R analysis. The samples collected symbolize the variations and fluctuations that are already in existence in the process. Preferably the samples are obtained from upper and lower tolerance limits. Generally a minimum of 10 samples are considered for best results.

This step is considered critical because if the samples are taken from a part of production that does not symbolize any variation then the purpose of doing this analysis goes down.

Measurements

After data collection, this is the time for measurements and calculations. For this step, followings points should be kept in mind:

- A single calibrated gage should be shared by the operators to have accurate measurements.

- The number of samples largely affects the results. Therefore it is important to always collect more than five samples at least.

- It is always a good idea to measure samples randomly.

- Each operator should take a minimum of two trial readings just to be sure about the results.

Evaluation of Gage R&R Results

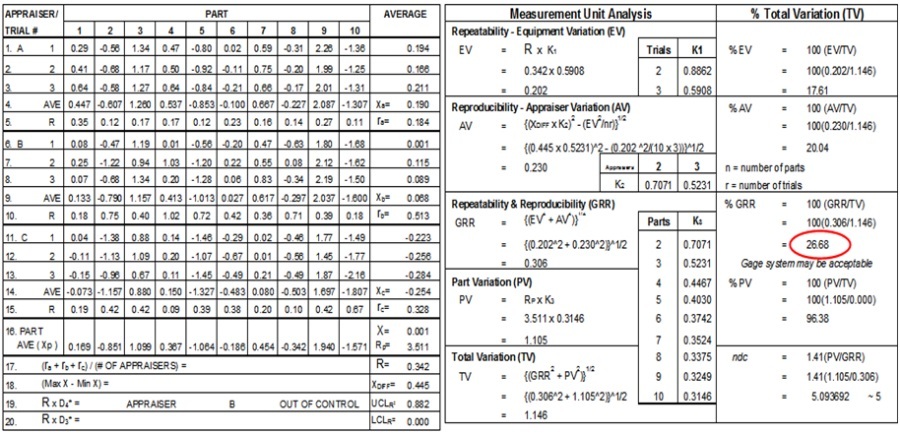

The evaluation of result depends upon the type of variation. The total variation report is split up into different sections. Such as:

The equipment variation portrays the repeatability of the machines and equipments or any measuring instrument. It is illustrated as the amount or percentage being part of total variation on the chart. If the results obtained are a value higher than 30 % that means there is a problem with the measuring equipment.

Next is the appraiser variation that portrays the reproducibility of the measuring system. This is also illustrated as a percentage being a part of total variation. The results having a percentage of greater than 30 % shows there is an issue with the operators that either they are untrained or trained with different techniques.

The part variation depicts the deviations with the products that were used for the analysis. In this case, if its value is less than 30 % it depicts the product or a part of product selected for the analysis was inappropriate.

Another one is the total tolerance report that scrutinizes the analysis against the tolerance of product being determined.

To conclude, the gage R&R analysis not only measures variations of the product but also of the appraiser. The method of conducting this analysis greatly affects the results.