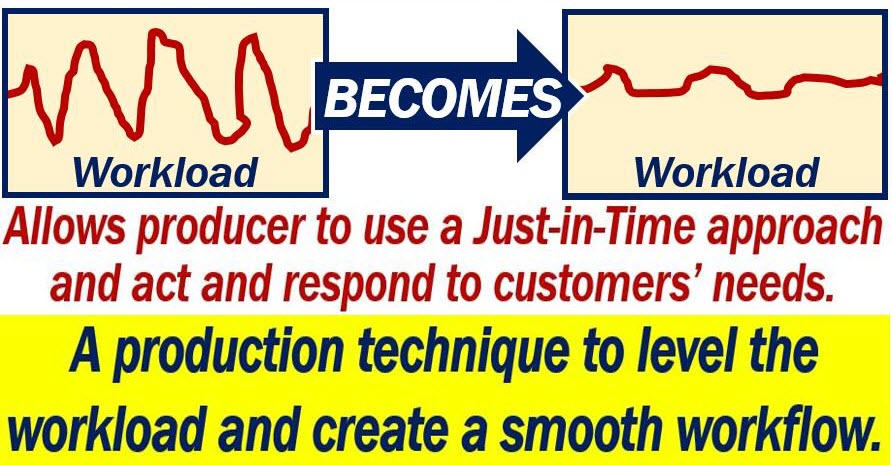

Heijunka (pronounced Hi-JUNE-kuh) is a Japanese word that signifies “leveling.” When executed accurately, heijunka efficiently and without flurry enables business to take care of demand while decreasing waste and interpersonal procedures.

As per numerous Lean experts, heijunka is better accomplished as a later-stage implementation in Lean organizations, long after streams have been recognized and s refined, when Lean legacy and philosophy are as of now profoundly embedded into materials cycles and process.

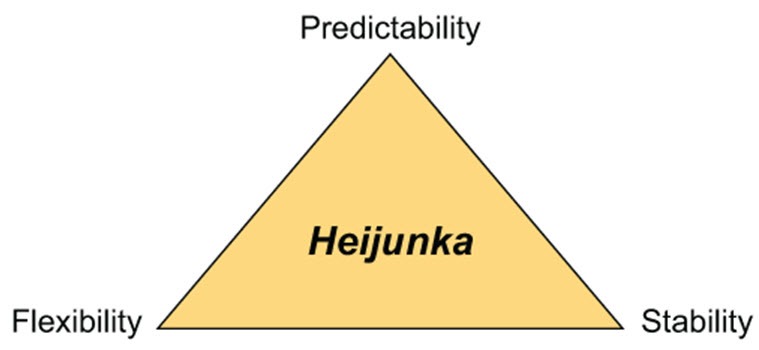

Heijunka is the relationship between predictability, flexibility and stability. When executed effectively, heijunka gives predictability by leveling request, Flexibility by diminishing changeover time and Stability by averaging manufacturing volume and sort over the long haul.

Leveling by Volume or Type

Let’s use heijunka board examples to make it clearer. How about we take a look at leveling volume? Say a cap maker gets orders for 500 of a similar cap for each week: 200 on Monday, 100 on Tuesday, 50 on Wednesday, 100 on Thursday, and 50 on Friday. Rather than trying to take care of demand in sequence of the orders, the cap maker would utilize heijunka to level request by delivering a stock of 100 caps near shipping to satisfy Monday’s order’s. Each Monday, 100 caps will be in stock. For the remaining week, generation will make 100 caps for each day, a leveling amount. The stock may look somewhat suspicious to lean purists, yet it has its fans, it is the strategy the Toyota Production System uses today.

Imagine a scenario where the circumstance includes numerous types of caps. Consider that orders are being set for cap models A, B, C and D. A mass producer will need to reduce waste around changeovers. Its generation calendar will look something like this: AAAAABBBCCDD.

In any case, imagine a scenario where a buyer chooses that order of A should be B. Imagine a scenario in which order volumes for A all of a sudden drop off and orders for C start to rise. A mass producer may be edgy to discover ability to make more C while it’s ‘A’ limits sits. To maintain a strategic distance from such waste, a heijunka production schedule may look like AABCDAABCDAB, with emphasis set on productive changeover times and buffer inventories that take care of demand for more popular productions.

Production Meets Demand

Before looking at setting up heijunka, how about we consider how lean master Michael Ballé describes the significance of heijunka to lean organizations: By producing each item amid every relevant time allotment, lead time is reduced and the business is nearer to meeting “real” orders.

That is the essence of heijunka: producing in tight and comfortable with orders. On the off chance that all item types are made (and stocked as necessary) consistently, flexibility is expanded, all hats should be sold (maybe not immidiately, but rather in the long run) and production will have the capacity to take care of peak demand time.

What is the catch? It’s changeover time. Heijunka depends altogether after putting a level of capacity (Ballé suggests 10 percent) into the changeover flexibility. “In the event that you need to make every product daily, which is somewhat the lean first objective, you have to decrease changeover time in like manner,” Ballé writes. Demand forecasts are not exactly right, and here and there totally off-base. Expanding changeover flexibility and efficiency protects the production line from interest ambushes set up by forecasts themselves.

The time frame of any heijunka implementation should start with takt time and end with a heijunka box.

Takt time is the time it takes to finish an item with a specific end goal to take care of client demand. It represents the rate at which clients purchase an organization’s product and at the end of a day or after week, it will indicate the amount of item A, B, C or D should be sent (or completed, as heijunka isn’t only to manufacture; it can be used as a part of front and back office settings, in any setting that has a perceivable supply and demand).

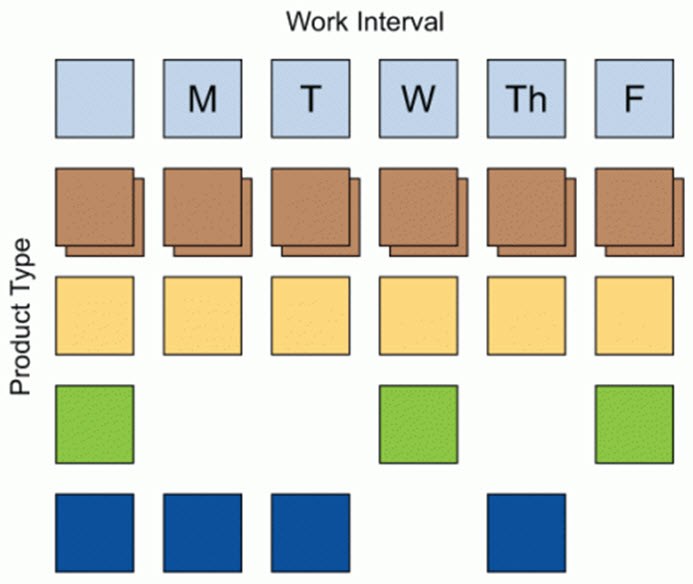

A heijunka box (it can likewise be a wheel or board) is a basic perception of production using kanban cards to flag creation as per a predetermined interval of work (e.g., per day). It is used by production staff on the floor and is profoundly respected in the visualizing processes.

Another of the heijunka board examples is seen below.