Kaizen continuous improvement is a Japanese management philosophy that focuses on making small, incremental changes to processes and systems to achieve better results over time. It has been widely adopted by businesses worldwide as a way to enhance productivity, quality, and efficiency. In this article, we will explore the concept of Kaizen, its key principles, and how to effectively implement it in your organisation.

Understanding Kaizen Continuous Improvement

Kaizen, which means “change for better” or “continuous improvement” in Japanese, was developed in Japan after World War II and was popularized by Toyota as a fundamental part of the Toyota Production System. The philosophy revolves around the idea that small, gradual improvements can lead to significant long-term enhancements in productivity and quality. Kaizen emphasises employee involvement, teamwork and a focus on eliminating waste in all forms, whether it be time, resources, or materials.

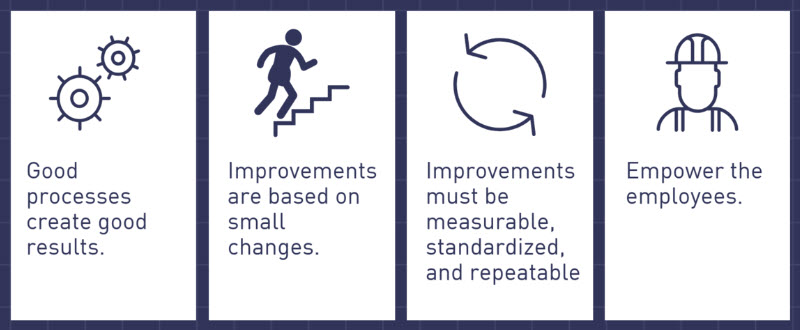

Key principles of Kaizen continuous improvement include.

- Continuous Improvement: Kaizen is not a one-time project but an ongoing process. It promotes the idea that everyone in the organisation, from the leadership to the frontline workers, should continuously seek ways to make improvements.

- Standardisation: Establishing and following standard processes is crucial to measure the effectiveness of improvements and to ensure consistency in operations.

- Waste Reduction: Kaizen identifies and eliminates waste in all aspects of operations, including unnecessary steps in a process, overproduction, inventory, and defects.

- Employee Involvement: Employees at all levels are encouraged to contribute their ideas for process improvement. This not only empowers employees but also taps into their firsthand knowledge of the work they do.

- Teamwork: Cross-functional teams often work together to identify and implement improvements. This collaboration helps bring different perspectives to the table and promotes a culture of mutual support.

Now that we have an understanding of the principles of Kaizen, let’s dive into how you can effectively implement it in your organisation.

Implementing Kaizen Continuous Improvement

Step 1: Establish a Kaizen Culture

To successfully implement Kaizen continuous improvement, it’s essential to create a culture that embraces and supports the philosophy. This culture should encourage all employees to be involved in the improvement process and promote the idea that even small changes can make a difference. Leadership should set the example by actively participating and supporting Kaizen initiatives.

Step 2: Identify Areas for Improvement

Begin by identifying areas within your organisation that can benefit from improvement. These could include manufacturing processes, customer service, inventory management, or any other aspect of your operations. Key performance indicators (KPIs) and data analysis can help pinpoint areas that require attention.

Step 3: Engage Employees

Engage your employees by encouraging them to share their ideas for improvement. Regular brainstorming sessions and suggestion boxes can be effective ways to gather input. It’s essential to create an environment where employees feel safe to share their ideas without fear of criticism.

Step 4: Prioritise Improvements

Not all ideas for improvement will have the same impact, so it’s crucial to prioritise them based on factors such as potential benefits, cost, and feasibility. Creating a simple scoring system can help in the decision-making process.

Step 5: Implement Small Changes

Once you’ve identified and prioritised improvement opportunities, start by making small, manageable changes. This might involve modifying a process, redesigning a workspace, or implementing new procedures. The key is to keep the changes simple and measurable.

Step 6: Monitor and Measure

After implementing changes, it’s important to track and measure their impact on performance. Use data and KPIs to evaluate the effectiveness of the improvements. This information will help you determine whether further adjustments are needed.

Step 7: Standardise and Sustain

When you’ve achieved a successful improvement, standardise the new process or practice to ensure it becomes a consistent part of your operations. Training and clear documentation can help with standardisation. To sustain the Kaizen culture, continue to engage employees in ongoing improvement efforts.

Step 8: Share Successes

Celebrate the successes and share the positive outcomes with your team. Recognition and feedback for their contributions can motivate employees to remain engaged and invested in the continuous improvement process.

Conclusion

In conclusion, Kaizen continuous improvement is a powerful approach to enhancing productivity, quality and efficiency in your organisation. By fostering a culture of continuous improvement, involving employees, and making incremental changes, you can achieve significant, long-term benefits. Remember that Kaizen is not a one-time project but an ongoing commitment to making your organisation better every day. Implementing Kaizen may take time, but the results will undoubtedly lead to better processes and greater success for your business.