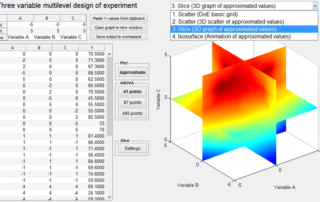

The Benefits of Design of Experiment During Development

The term experiment is characterized as the systematic process carried under controlled conditions keeping in mind the end goal to find an obscure effect, to test or set up a theory, or to delineate a known effect. While analysing a procedure, design of experiment are frequently used to assess [...]

How to Use 8D Problem Solving Within Your Organization

The 8D problem solving is a methodology which is specifically designed to find the root cause of the problem, devise a short term fix and implement a long term solution to prevent recurring of the problem. 8D is an excellent step to improve the quality of a product when [...]

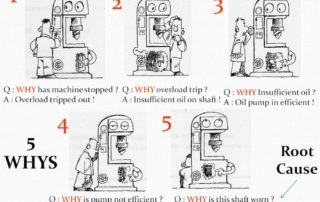

5 Whys Problem Solving Within Manufacturing

The 5 whys problem solving strategy is targeted at discovering the root cause of a particular problem. This was developed by Toyota and is very effective. The fundamental idea is to get to the root of a problem by continuously asking “Why?” for at least five times until you [...]

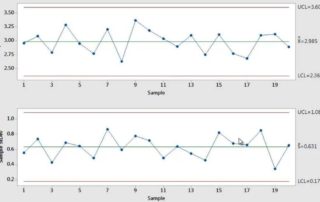

Statistical Process Control Tutorial on How to Implement SPC

Statistical Process Control (SPC) is an industry-standard approach for assessing and managing quality throughout the production process. Quality data is acquired in the form of product or procedure capacity right away during production. Setting up Statistical Process Control is a process in itself, calling for organizational dedication across functional [...]

Developing a NCR Process Within Your Organization

When we talk about non-conformance, it means that something is not right indicating that a problem has emerged and we must address it in order to fix what went wrong. An organization has to deal with non-conformances by addressing them with corrective actions. In a non-conformance report (NCR) the [...]

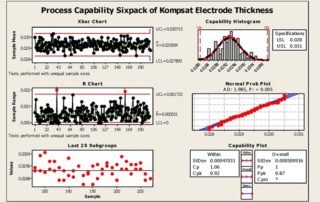

Determining the Manufacturing Capability of a Process

A uniform product having very low defect rate is usually given by a capable process. The comparison of yield of an in control process with the specified limits is called as manufacturing capability. It is also known as process capability. Manufacturing capability and defect rate are inversely proportional to [...]