It’s a misconception that Takt time vs Cycle time are the same things. These are two different things and the difference should be clearly understood in a manufacturing and assembly environment.

Cycle time is the time required to finish one unit. To better understand, Takt Time is a calculation used to understand customer demand. It is important to understand your customer demand so you can meet it. The easiest way to remember the Takt Time calculation is it to think, “TD” or “Touch Down.” Takt = Available Time / Customer Demand.

Cycle time is the time required to finish one unit. In detail we can say, cycle time is the amount of time it takes to complete a cycle of action; completion of a specific task from start to finish. More specifically it is the measured time that explains how often a part is completed by a particular process.

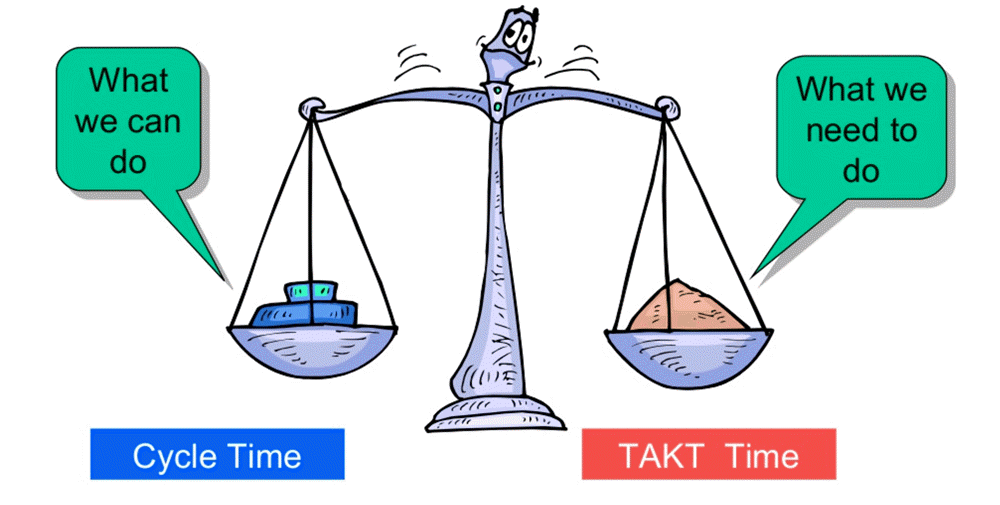

Takt time vs cycle time are different but they need to be the same. The mismatch between the times can create a lot of headache. A cycle time is that how often a part is completed by a particular process where as the takt time is a customer’s demand calculation that tells you how often a part should be completed in a process to meet the costumer’s requirement. In other words, a cycle time is the actual time which takes to complete your widget, and the takt time calculation let you know if you’re producing fast enough to meet the customer’s requirement.

If the cycle time is more than Takt time it means that you’re not producing fast nought to complete the customer’s demand, which will eventually results in loss of sales, poor satisfaction rate, expedite freight charges and poor metrics. This is one of the reasons why companies hold safety stock which is a complete waste of inventory. If the cycle time is less than takt time, it means that your company is overproducing and the process could be overdesigned and overstaffed which is also a waste of resources.

- Over-designed: One of the main reasons is that too much money and too much efforts may have been spent on the design which is resulting in depreciation that weighs on your business for years to come.

- Over-Staffed: You have too many employees on the process.

- Over-production: Producing more than your requirements which lead to excess inventory, opportunity cost, and paying wages for the product that may not sell. Overproduction is seen by many as the most detrimental waste because it can lead to all the traditional 7 forms of waste.

Theoretically, if the Cycle time and Takt time are same, then there will be no risk of under or over production. However, if there is a quality issue or a machine problem which is not creating a perfect widget, these are the challenging factors in manufacturing. That is why there is a benefit of having a Cycle time less than Takt time. In other words, you have the ability to build faster than the customer’s demand not by an extreme amount but a slight amount to equalize the difference or to mitigate a small hiccup in manufacturing. Please note that if you schedule accordingly, meaning you build the exact same amount as per the customer’s demand, it will never result in over producing or under producing.

Based on the above it should now be clear what the difference is of Takt Time vs Cycle Time.

Common Misunderstandings of Takt Time vs Cycle Time

Misunderstanding 1

I have found there is a misunderstanding of Overall Work Content, many people take the Cycle Time complete (Machine + Manual) which is not right, they must use the “Manual” Overall Work Content (Total Manual Cycle Time).

Misunderstanding 2

There is another misunderstanding about the representation of TT, many people don’t understand this concept how to interpret and calculate the Number of Resources when they have operators working in parallel.

For example; when there are operations that are not possible to be separated, the activity must be done from the beginning to the end by one operator at time; and if the cycle time is greater than Takt Time; then you need to use more than one operator to cover the rate needed, this means to have two or more operators working in parallel, for this case the Takt Time must be different.

You should never use the average of those operators as the Manual Work Content, you need represent as it is and make the calculations using other Takt Time equivalent.