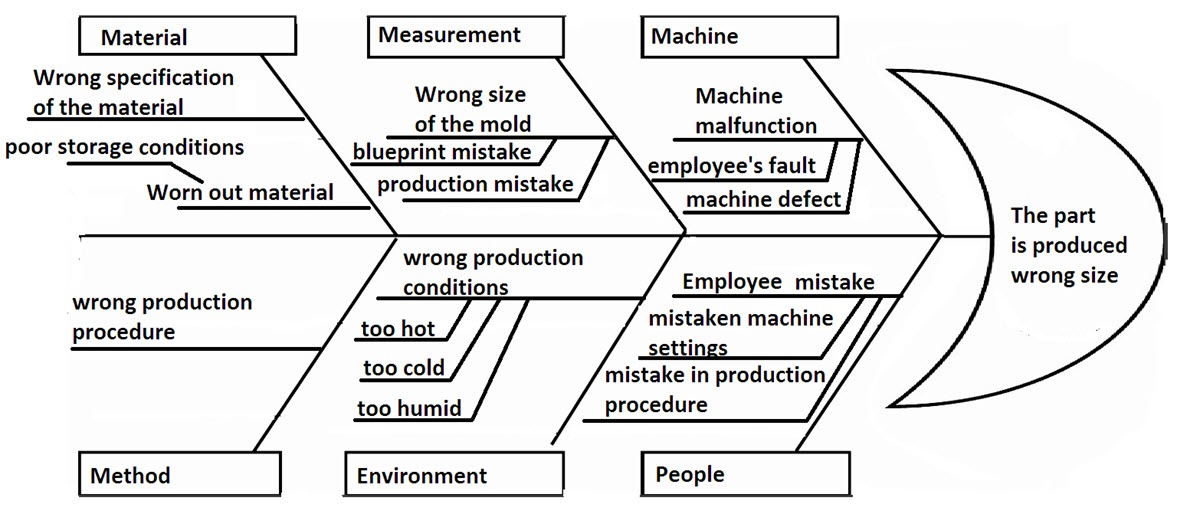

How to Create a Fishbone Diagram

Problems are a part of any business and they can occur at different times as well as in various different forms. The main thing is that we possess the potential to identify the cause of these sorts of problems in a suitable way. In simple words, a fishbone diagram is a diagram that looks [...]