Implementing a flexible manufacturing system signifies a commitment and significant investment by the organization. It is predominant that the system installation precedes by in-depth planning.

Its operation should be characterized through excellent management of all the resources, such as people, parts, pallets, tools, and machines.

What Is Flexible Manufacturing System?

Before going ahead, we must tell you that flexible manufacturing system is an industrial procedure that enables to use equipment for more than one thing, somewhat they related to other things as well. This is also one of the elements used within lean manufacturing.

The Objective of a Flexible Manufacturing System

The primary purpose of the flexible manufacturing system is to provide the needed speed to alter the prevailing market conditions rapidly without compromising on quality.

Implementation of a Flexible Manufacturing System

The essential thing to consider when implementing flexible manufacturing system is the products that will be produced through the system.

It must be designed by keeping a specific range of products in mind. The limit must be decided before going ahead. The product family that is going to be processed must be defined. The product family that is going to be produced must be common or similar at least.

The types of products and their requirements for processing must be regulated and for that company needs to check the system first.

The weight and size of the products determine the extent required for the production and capacity of the handling system.

The production volume and quantity must only be determined by checking the number and size of the machines available. Production volume is also a vital factor in implementing the flexible manufacturing system.

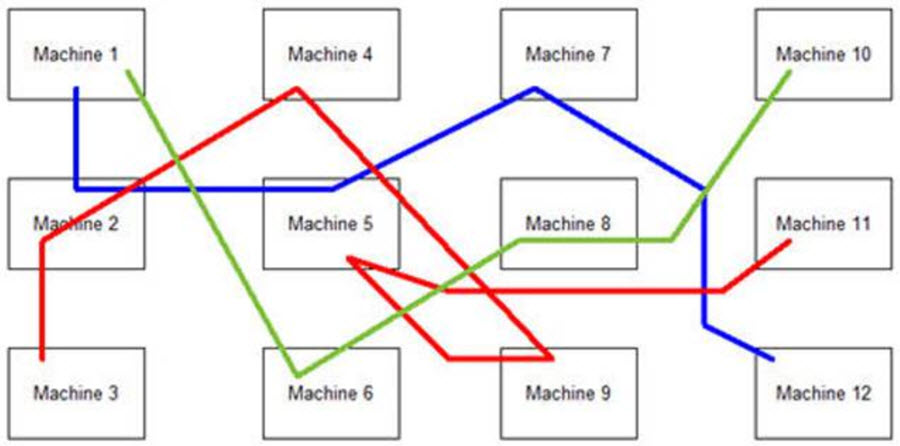

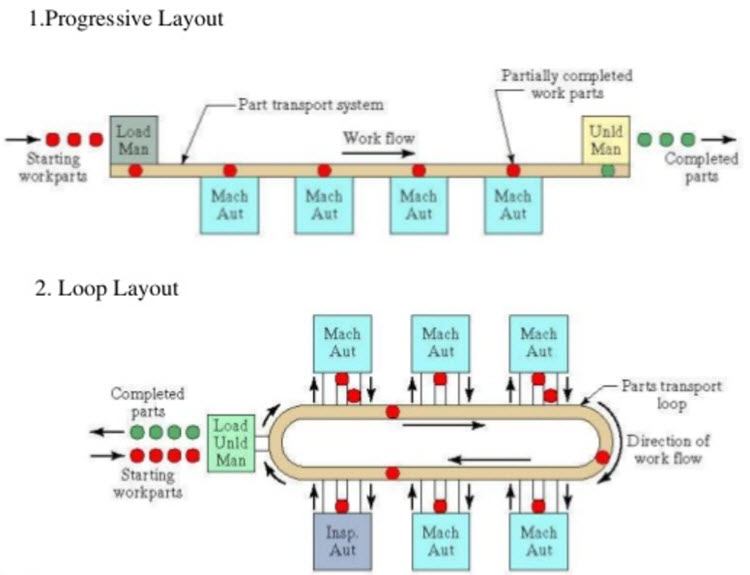

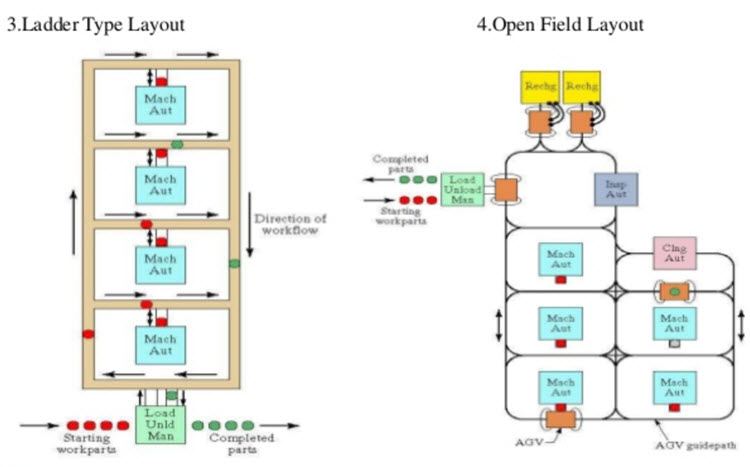

If variations in the production order are minimal, then the company must go for inline flow as the most appropriate production flow for implementing flexible manufacturing system. A loop is recommended if a variety of products increase. If there is a significant variation in the processing stage, then an open field or ladder layout is appropriate.

One does not forget about material handling layout and equipment because they are closely related. The kind of handling system limits the layout choice to some extent.

The work in process in the flexible manufacturing system is an important feature in implementing the efficiency and utilization of the manufacturing system.

If the work in process is too low, the production area will be starved for work, and it will not result in maximum utilization. If the work in process is too much, then a gridlock may occur. In order to implement the flexible manufacturing system, one must plan the job before the operation.

So, this is the fundamental approach for any company to go for. Now, there are a lot of advantages of implementing flexible manufacturing system, but there are some disadvantages too. Let’s look at them below:

Pros and Cons of Implementation of Flexible Manufacturing System

Pros

- The labor cost is lower because it tells you about the exact number of workers organization need. It assists you in the reduction of exceeding labors.

- The lower cost changes are fast from one part to another part. It will enhance the capital utilization.

- It reduces the inventory because of the programming and planning accuracy.

- Because of automated control in a flexible manufacturing system, it remains consistent and produces better quality.

- Lower the unit of output and cost due to superior productivity by using the exact number of workers.

- It saves you from the indirect labor by reducing repairs, errors, rejects, and rework.

Cons

- There is a limitation of ability in adapting the changes occurring in the product mix. For instance, the machines have limited capacity; the necessary tools for products (even if they are from the same family) are not always feasible for flexible manufacturing system.

- The planning before the activity is substantial.

- Costing is in millions of dollars, it is expensive.

- The manufacturing system is sophisticated.

Wrapping It Up

So it was all about how to implement a flexible manufacturing system. The flexible manufacturing system is costly, and it is complicated too, this is the reason that industry is accepting it slowly. However, many companies prefer it.