How to Use Force Field Analysis when Implementing a Change

Kurt Lewin's Force Field Analysis Basically, Force field analysis is a technique of change management initially considered by the psychologist Kurt Lewin to be practiced in social situations. No doubt it is a very significant strategic tool that can be used for understanding what is required for implementing a [...]

What are the Steps in a Six Sigma Analysis?

What is a Six Sigma Analysis? A Six Sigma Analysis is a quality-control methodology developed by the engineers of Motorola in 1986. It is a data-driven analysis used in order to decrease faults or shortcomings in a business or production process. Fundamentally, Six Sigma Analysis includes gathering and leveraging [...]

Heijunka Used for Leveled Scheduling

What is Heijunka? In the corporate world, executives and managers have to be conscious of the fact, that it takes some effort to maintain a steady work flow. Basically, Heijunka is a lean methodology used for dropping the irregularity in a manufacturing process and reducing the possibility of overload. [...]

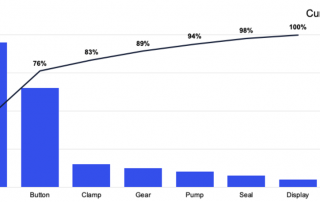

How to Draw a Pareto Chart and What It Will Show

Pareto chart is simply a basic quality tool to help identify frequent defects, complaints, or other factors as part of a data analysis study. It is a deceivingly simple concept which can have huge benefits when analysing data. The Pareto owns its existence to Vilfredo Pareto. The famed economist [...]

Driving and Restraining Forces in Field Force Analysis

In our life, we often come across a point where we have to make a tough decision for ourselves such as starting a new chapter or embrace a change. At that point, we sometimes find ourselves helpless, clueless and with no solution to the problem. While assessing if and [...]

How to Implement Kaizen in an Organization

Kaizen is continuous improvements where changes are required in organization’s processes. The approach could either be a one time implementation or a step by step change over time. One of the top benefits provide by Kaizen is that it is continuous and not a time limited process. Kaizen offers [...]