Lead Time Reduction and Why It Is Important

Lead time is one of the crucial factors in today's fast-paced and development business environment. Lead time is basically the time required from the shipments to be ordered and until it is received. This time calculation is vital for attaining the correct reorder formula and maintenance of stock that [...]

Implementing 5S Workplace Organization and Standardization

Basically 5S is a philosophy and an approach of organizing and managing the workplace and course of work with the commitment of increasing efficiency by reducing waste, enhancing flow and decreasing process irrationality. It uses a list of five Japanese words: Seiri (Sort) Seiton (Set in Order), Seiso (Shine), [...]

The 5 Principles of Lean Production and Their Implementation

The term Lean comes from manufacturing practices where it was initially used to improve effectiveness in production. It is now used across a lot of industries including software houses, manufacturing industries, business companies and even the construction industry. This method is for continuous improvement in work and management. It [...]

What Are the Lean Six Sigma Tools?

Lean Six Sigma Lean Six Sigma is a management approach for problem solving and process improvement by combining various tools of Six Sigma as well as Lean Manufacturing. It mainly involves procedures and methods of Six Sigma as the pillar of the system like DMAIC. Its objective is to [...]

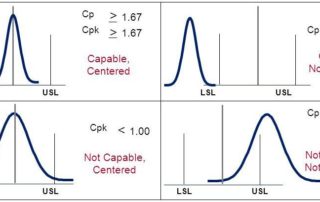

How to Calculate Cp and Cpk Values and When to Use Them

What is Cp and Cpk Basically, for a process Cp and Cpk are taken as short-term prospective capability measures. In Six Sigma it is desired to define quality of the processes in terms of sigma. The rationale behind this is that it offers a stress-free manner to state the [...]

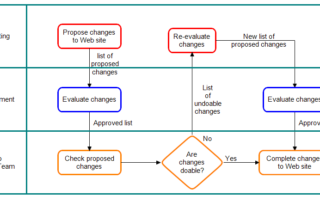

What are the Advantages and Disadvantages of Process Mapping?

Process Mapping Basically, a process map can be defined as a planning and management tool which visually explains the work flow. It summarizes the job duties executed to finish a particular task at the place of work. It can be utilized to provide a clear framework for production processes, [...]