You ever feel like there is something wrong, but you can’t put your finger on it? Well, before you can fix the problem, you need to recognize it first. The longer you stay in that one place, the more you’ll struggle in seeing the problem, which we call “waste.” It is the waste around you that affects your productivity. So how to remove this waste you ask? One simple way is to take a waste walk. This process makes the hidden waste visible again. Just to add some useful information, a waste walk should not be mixed with a Gemba walk as both are different from the other. A waste walk is usually a pre-planned visit to the workstation to observe all the happenings and to identify the camouflaged waste.

Why Create a Waste Walk Checklist

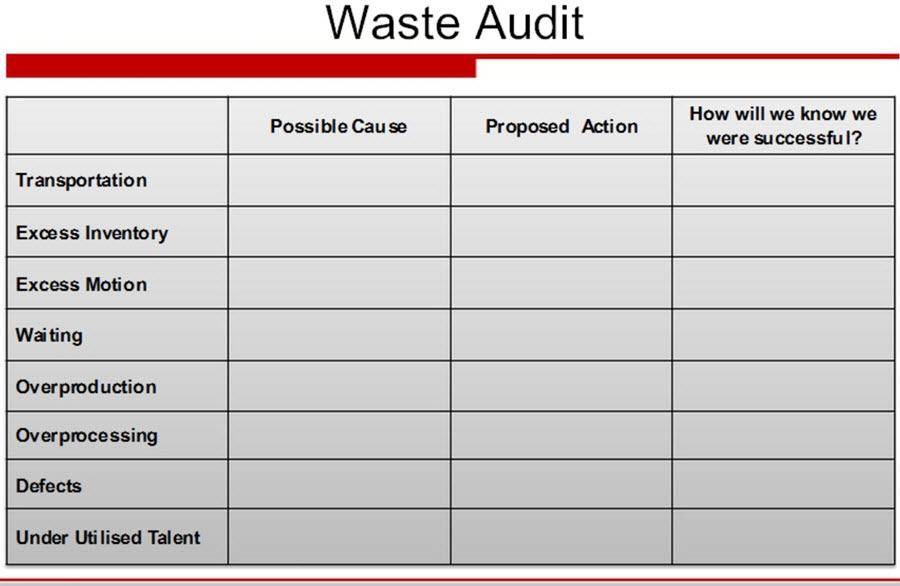

The main reason for creating a waste walk checklist is to help in recognizing any non-value added activities within an automated process. A standard waste walk checklist is composed of 8 deadly wastes; they are Waiting, Overproduction, Rework, Motion, Processing, Inventory, Intellect, and Transportation.

When to Use a Waste Walk Checklist

We use the waste walk checklist during the assessment phase of the waste walk. The waste walk checklist has to be created prior to conducting the actual waste walk.

Objectives of a Waste Walk Checklist

- To understand the problems that are pointed out in the progress of the current-state map.

- To provide a format that will remain to socialize the redesign work.

- To provide a prospect which will gather staff ideas relating to the current-state difficulties.

Above I have explained to you what a waste walk checklist is, its usage, and its objectives. Before I move on towards the guidelines on making your waste checklist more effective, I am providing a little information about the 8 wastes that are present in the checklist.

The 8 Wastes Present in a Waste Walk Checklist

Time

- Waiting for people or services to be delivered, the time when people, processes or equipment are idle.

Defects

- All the waste that is related to costs for the purpose of inspection of defects in materials, customer complaints, repairs and various processes.

Motion

- All the unnecessary movement or motion that doesn’t add any value.

- Movement that is too slow or too quick.

Transportation

- Transferring, conveying, picking up, piling up, and setting down or else moving unnecessary

Inventory

- Unnecessary amounts of materials, supplies, or information for any period of time.

- Having excess inventory is having more on hand than what is actually used and needed.

Processing

- Excessive operations and processes which were traditionally accepted as compulsory.

Overproduction:

- The Production of excessive material in huge amounts which is unnecessary.

Underutilization of People

- The failure to completely utilize the talents of people and of their time along with the lack of training.

Above you have the complete description of the 8 wastes that you might oversee. With the help of their description it is easier for you to identify them.

Below I have provided some guidelines which can help you in creating an effective waste walk checklist.

Guidelines

- Have a small meeting with the all team members.

- The meeting should have a purpose.

- The meeting should provide information about different types of wastes to all team members.

- When current state problems are identified, then copies containing information about them should be passed on to other members.

- Assign particular areas to walk with your team members.

- You need to walk the process depicted on your map; you can do that as a group to confirm the areas to address.

- You need to explain to all the team members about the things you people are observing and what your intended purpose is. Share your vision and the map along with various waste examples so that it can describe the objectives of this observation activity.

- You need to study the whole process/activity for almost 30-45 minutes.

- Next, you need to take notes of all work which feels like waste to you.

- Once that is complete, you need to return to your team members and discuss about your observation.

- Next what you need to do is to match all the wastes which you have seen to the problems that were previously identified in the current-state map, you can do this as a team. During the walk, if you encounter other issues then place them all on the checklist.

- This is the last step; you need to place the results of the waste walk right next to the checklist which is being shared and used in your area. You can use the results to continue to socialize the system level and current state problems that irritate the process and people.