How to Implement 5S in the Workplace

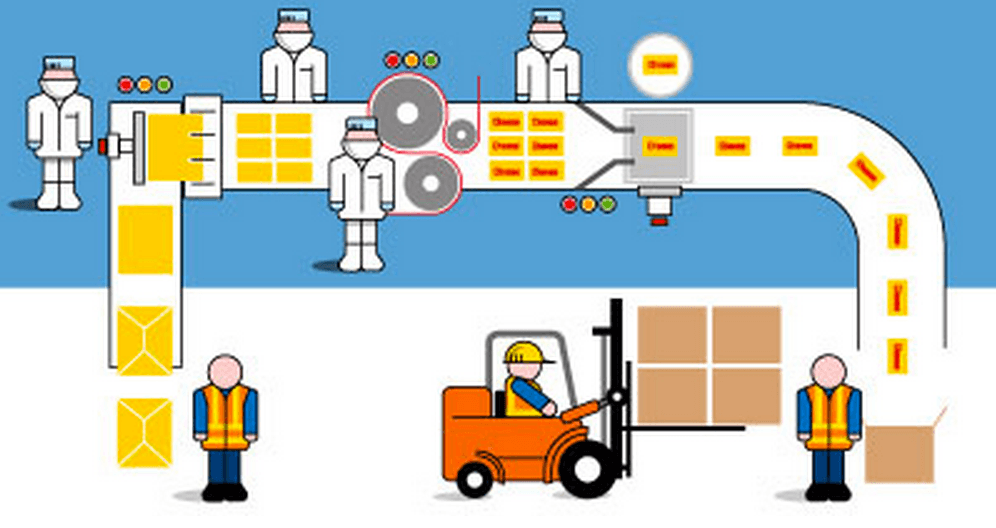

5S in the work place is one of the primary tools that can be implemented in an organization as a starting point to change the culture of an organization to a continuous improvement culture. A 5S implementation characterizes the principal guidelines to wipe out waste and keep up an efficient, safe, and clean workplace. [...]