Statistical Process Control (SPC) is an industry-standard procedure for measuring and monitoring quality during the manufacturing process. Quality data as Product or Process estimations are acquired in real-time during manufacturing. This data is then plotted on a graph with predetermined control limits. Control limits are determined by the capability of the process, though the client’s needs determine specification limits. This article will review how to use SPC in manufacturing and some of the benefits it brings to your business.

How to Use SPC in manufacturing

Before performing SPC or any new quality system, the manufacturing process ought to be evaluated to determine the main regions of waste. A few cases of manufacturing process waste are reworked, scrap and excessive inspection time. It would be most useful to apply the SPC tools to these areas first. During SPC, not all dimensions are checked because of the cost, time and population delays that would incur. Preceding SPC implementation the core or essential characteristics of the design or process ought to be identified by a Cross Functional Team (CFT) during a print survey or Design Failure Mode and Effects Analysis (DFMEA) exercise. Data would then be gathered and checked on these key or essential characteristics.

Collecting and Recording Data

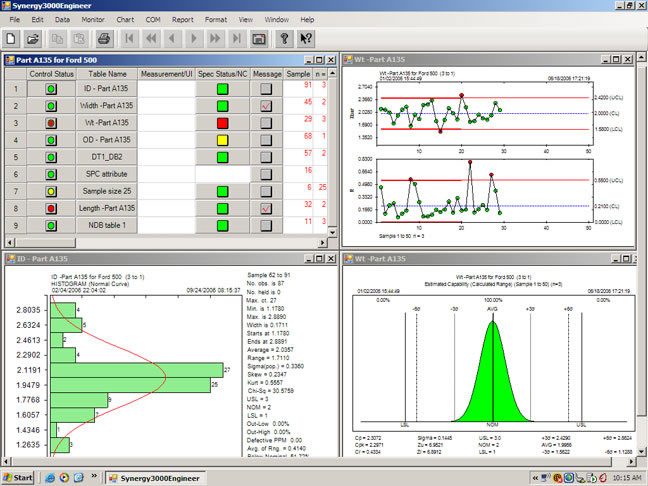

SPC data is collected in the form of measurement of an items dimension or process instrumentation readings. The data is then recorded and tracked on different sorts of control charts, based on the kind of data being collected. It is important that the right type of chart is utilized to gain value and get helpful information. The data can be in the form of continuous variable data or attribute data. The data can likewise be collected and recorded as individual values or an average of a group of readings. Some general’s guidelines and cases are listed below. This list is not all comprehensive and provided just as a reference.

Variable data

- Individual – Moving Range chart: to be utilized if your data is individual values .

- X bar – R chart: To be utilized on the off chance that you are recording data in subgroups of 8 or less.

- X bar – S chart: to be utilized if your sub-group size is greater than 8.

Attribute data

- P graph: For recording the number of deficient parts in a group of parts.

- U graph: For recording the number of defects in each part.

Control Charts

A standout amongst the most widely used control diagrams for variable data is the X-bar and R chart. X-bar represented the average or “mean” value of the variable x. The X-bar charts illustrate the variation in the sample means or average. The Range chart demonstrates the variation within the subgroup. The range is the distinction between the highest and lowest value. The following steps are required to build an X-bar and R chart:

Once the chart is setup, the operator or technician will measure various samples, add the values together then compute the average. This value is then recorded on a control chart or X-bar chart. The range of the subgroups is additionally recorded. The sample measurement ought to be taken and recorded in regular interims, including date and time to track the stability of the process. Look for any special or assignable causes and change the process as important to maintain a stable and in control process.

The X-bar and R chart is just one case of the distinctive control charts available for process monitoring and improvement.

Analyzing the Data

The data points recorded on a control chart should fall between the control limits as far as possible, given that only common causes and no special causes have been identified. Common causes will drop between the control limit while special causes are generally outside of the control limit. For a process to be considered in statistical control there ought to be no special causes in any of the charts. A process in control will have no exceptional causes distinguished in it, and the data should fall between the control limits. A few cases of common cause variation are as per the following:

- Variation in material properties within specification

- Seasonal changes in ambient temperature or humidity

- Normal machine or tooling wear

- Variability in operator controlled settings

- Normal measurement variation

Exceptional causes generally fall outside of control limit or show a radical change or shift in the process. A few cases of special cause variety are underneath:

- Failed controllers

- Improper gear adjustments

- A change in the measurement system

- A process shift

- Machine breakdown

- Raw material properties out of design specifications

- Broken tool, punch, bit, and so forth.

- Inexperienced operator not familiar with process

While monitoring a process through SPC charts, the inspector will approve that all data points are inside control limits and look for trends or sudden changes in the process. If any special causes for variation are identified, appropriate action ought to be taken to determine the cause and actualize corrective actions to restore the process to a state of statistical control.

Benefits of SPC in Manufacturing

- Lower manufacturing costs

- Improved forecasting

- Decreased issue to solution lead time

- Correct standards

- Less inspection

- Better client relations

- Reliable measures of capability

- Stable processes

- Improved product quality

- Realistic Specification

- Decreased cycle time

Overall then there are many benefits to using SPC in manufacturing which is why it is widely used within the industry. SPC can also be used in many other industries to monitor if a process is in control, for example to determine if the response time in a call center is within statistical control.