In the pursuit of operational excellence, businesses across manufacturing, services, and even healthcare are turning to value stream mapping (VSM) as a powerful way to analyse and improve their processes. By visualising the flow of materials and information from start to finish, organisations can identify waste, streamline operations, and boost customer value. However, the benefits of VSM depend on following the right value stream mapping steps in a structured and consistent manner.

This article explains what value stream mapping is, outlines the key steps to carry it out effectively, and shows how it supports continual improvement.

Understanding the Purpose of Value Stream Mapping

Value stream mapping is a lean-management method used to depict every step involved in delivering a product or service. Unlike simple process maps, VSM includes both the flow of physical goods and the information that controls that flow. It also highlights areas of waste, whether in time, materials, or effort, that can be reduced or eliminated.

By making the process visible, teams can more easily pinpoint bottlenecks, duplication, delays, or miscommunications. This makes value stream mapping a critical tool for continuous improvement initiatives, as it focuses on the entire system rather than isolated issues.

Key Value Stream Mapping Steps

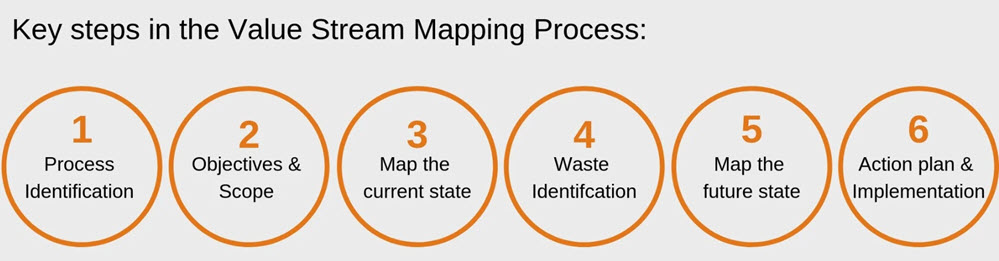

The process of creating and using a VSM can be broken down into several essential stages. Following these value stream mapping steps ensures that the exercise produces meaningful insights rather than just a decorative diagram.

Step 1: Define the Scope and Objectives

Before picking up a pen or opening software, decide which process or product line you are mapping. This includes clarifying the start and end points of the stream, the timeframe for analysis, and the objectives you hope to achieve. For example, you may want to reduce lead times, improve quality, or lower costs. Clear boundaries help keep the mapping exercise focused and relevant.

Step 2: Gather the Right Team

Value stream mapping works best when it involves a cross-functional team. Include people from all parts of the process, operators, supervisors, quality control, procurement, and even customer service, so that you capture the full picture. Each participant contributes knowledge that might otherwise be missed.

Step 3: Collect Data

Accurate data is the backbone of an effective VSM. Gather information on:

- Process times and cycle times.

- Lead times and waiting times.

- Inventory levels at each stage.

- Error or defect rates.

- Information flow and communication methods.

Where possible, observe the process in real time rather than relying solely on reports. This ensures that your map reflects actual conditions, not idealised procedures.

Step 4: Map the Current State

Using the collected data, create a diagram that shows each step in the process, the time it takes, and the flow of materials and information. Standard VSM symbols help communicate the different elements, such as processes, data boxes, inventory triangles, and communication arrows. The current state map is your baseline for identifying waste and inefficiencies.

Step 5: Identify Waste and Opportunities

With the current state map complete, look for areas that do not add value from the customer’s perspective. Common wastes include overproduction, unnecessary movement, excess inventory, rework, and waiting times. These are your targets for improvement.

Step 6: Design the Future State Map

The future state map represents your vision for an optimised process. It should remove or reduce waste, streamline communication, and enhance value delivery. Consider changes such as reducing batch sizes, introducing pull systems, improving information sharing, or eliminating redundant steps.

Step 7: Develop an Action Plan

An action plan bridges the gap between your current and future states. Assign responsibilities, set deadlines, and identify metrics for measuring progress. Continual improvement relies on translating insights into concrete actions.

Embedding Value Stream Mapping in Continual Improvement

Carrying out value stream mapping once can lead to significant gains, but its real power lies in repetition. As conditions change, whether due to market demand, technology, or internal factors, the process should be revisited. Embedding the value stream mapping steps into your organisation’s improvement cycle ensures that processes remain efficient and responsive.

This means:

- Scheduling periodic reviews of your value stream maps.

- Tracking performance against your future state goals.

- Updating maps when processes change.

- Using maps as a training tool for new staff.

By making VSM part of a continuous improvement culture, you avoid slipping back into inefficient habits.

Common Pitfalls to Avoid

While value stream mapping is straightforward in principle, certain missteps can reduce its effectiveness:

- Overcomplicating the map: Including too much detail can make the diagram difficult to read. Focus on what matters for improvement.

- Working in isolation: Mapping without input from all stakeholders risks missing critical issues.

- Failing to act: A VSM is only valuable if it leads to real changes. Avoid letting the exercise end with a map and no follow-through.

- Ignoring the information flow: Many inefficiencies stem from poor communication, so ensure this is clearly represented.

Avoiding these pitfalls helps ensure your VSM project leads to lasting benefits.

Conclusion

Value stream mapping is a powerful method for identifying waste, improving efficiency, and boosting customer value. By following the correct value stream mapping steps, from defining scope and gathering data to mapping the current state and designing the future, you create a clear roadmap for improvement.

When embedded into a continual improvement programme, these steps help organisations remain competitive, responsive, and customer-focused. The key is not just creating a map, but using it as a living tool that evolves with your business.