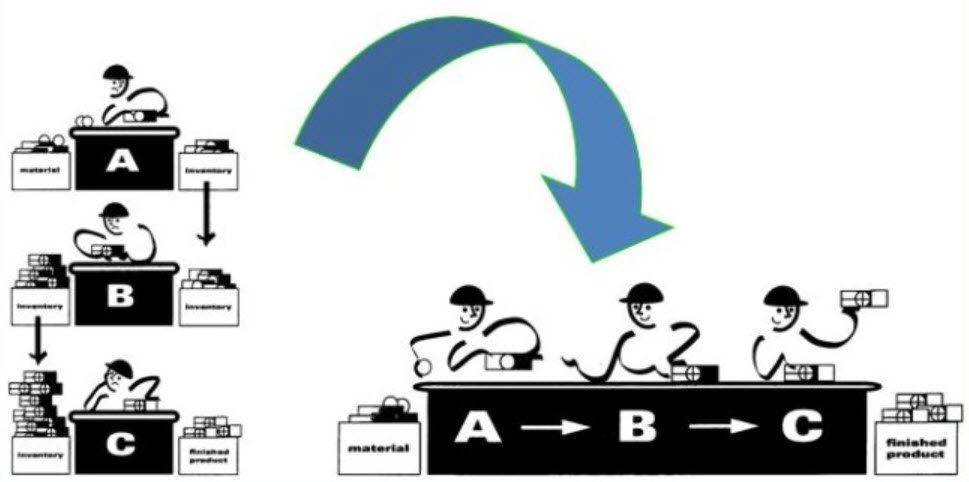

In “One piece flow” production, the product transfers from one phase to the next phase with one piece at a time. This approach is different from lot production where a number of units are prepared at an agreed stage and then every unit is moved to the next level at the same time. One piece movement is encouraged by majority of the operational excellence practitioners.

Benefits of One Piece Flow

The manufacturer can enjoy lots of benefits by implementing one piece flow as no idle time is there between the units.

Minimize Financial Loss

The piece that is completed first cannot transfer to the next stage with lot production until the last piece is finished in the lot. So in that scenario it is quite evident that first piece remains unusable until the full lot is processed. One piece flow also allows the manufacturer to stop the production process earlier in case of any defect and the problem can be fixed. Moreover, the defect happens just because of that existing unit. The defect can be avoided in the next units all together because the problem is fixed immediately by the manufacturer. In this way the manufacturer is able to save any kind of financial loss.

Improves Flexibility Level

In addition to that, one piece flow improves the flexibility level in a great way because it is quicker as compared to batch and queue. Due to the factors of the one piece flow being faster, it is possible to wait longer to plan the order and yet deliver in time. Consequently, it allows us to comply with last minutes changes from the customer and as it’s very common that despite of the industry we work in customers love to change their preferences. Sampling inspection takes place after the production of a certain step with lot production. If a defect is yielded during inspection then the complete lot is suspected. In order to find that defect all parts must be reviewed in the lot because we can expect more defects in the lot.

Minimize Wastes

If an organization wants to get rid of the eight categories of waste then all individual activities process must be united and synchronized by implementing one piece flow. To accomplish this purpose there will be need of improved designs so that the travel distance between successive operations can be reduced. In the implementation of one piece flow the most common approach is known as Work Cell. Workstations are moved near to each other for decreasing transport between them. In a conventional plant setting the manufacturing departments carry out specific tasks including grinding, welding, fabrication, drilling, and assembly by utilizing its specific workforce that has got the single skill. The main emphasis of the Work Cell approach is the flow of product and the individuals manage themselves in accordance with the demands of customer, by altering the method in which work content is separated. On the other hand, the manufacturing cells are intended to offer entire products to an inner work cell or an outside customer. More to the point, work cells execute a number of procedures or tasks and call for multi-skilled workforce who has got the quality of flexibility.

Decreases operator movements

Furthermore, the operator movements are also reduced when the cell is U-shaped and in that case the work cell can be referred as the U-cell as well. So to complete each and every process activities in the least amount of physical space the formation of U-shaped work cells is a must have and most importantly they must be linked. The standards of high-quality work cell design incorporates organizing the work in order, utilizing a flow in counter clockwise, placing machines and processes close as one, and putting the last operation near to the initial operation. For producing the approval for manufacturing the work cell must be planned to achieve line balance with regard to takt time, and Kanban. The work cell employees are authorized by the organization to take all necessary measures to meet the needs of internal and external customers.

The amount of persons within the cell establishes the quantity of WIP (Work in Process) in the work cell and the cycle time. In some companies the employees face a multifaceted environment where customer demand differs and various production lines are offered for diverse product families. In that case by simply adding up and eliminating people from work cells the principle of Work Cell can be helpful to adjust the cycle times so a proper response to these changes of demands can be complied. Depending on the kind of process, whether or not, work cells can be implemented in two or more workplaces.