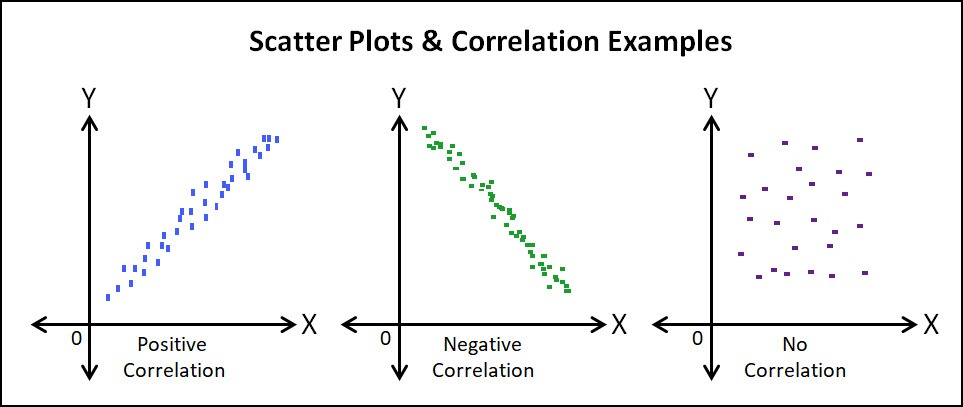

Interpreting a Scatter Plot and When to Use Them

A scatter plot is a two-dimensional data representation that uses dots to show the values acquired for two different variables, one plotted along the x-axis and the other plotted along the y-axis. For instance this scatter plot below demonstrates the height and weight of a fictitious set of children. When entering a huge amount [...]