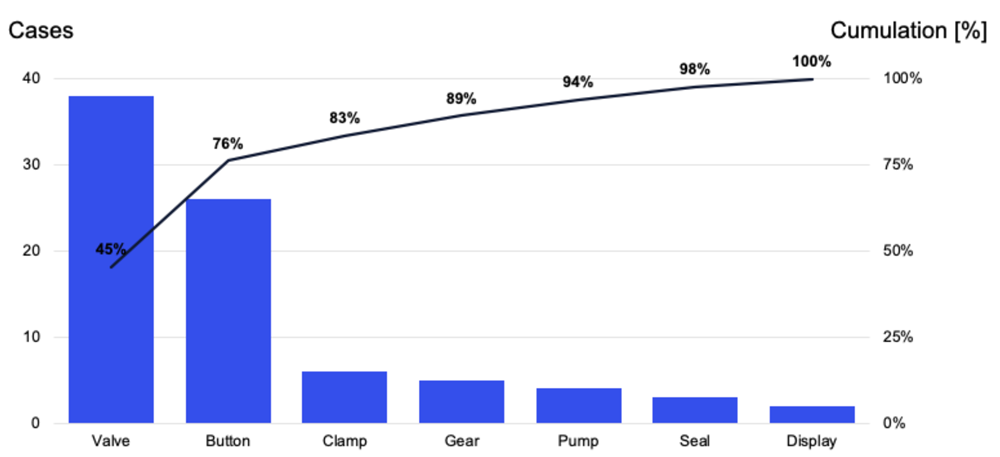

How to Draw a Pareto Chart and What It Will Show

Pareto chart is simply a basic quality tool to help identify frequent defects, complaints, or other factors as part of a data analysis study. It is a deceivingly simple concept which can have huge benefits when analysing data. The Pareto owns its existence to Vilfredo Pareto. The famed economist evidenced that 80% of the [...]